Acrobatic & 3D Scratch Builds

Extra - 35 (mkIII)

--== Specifications ==--

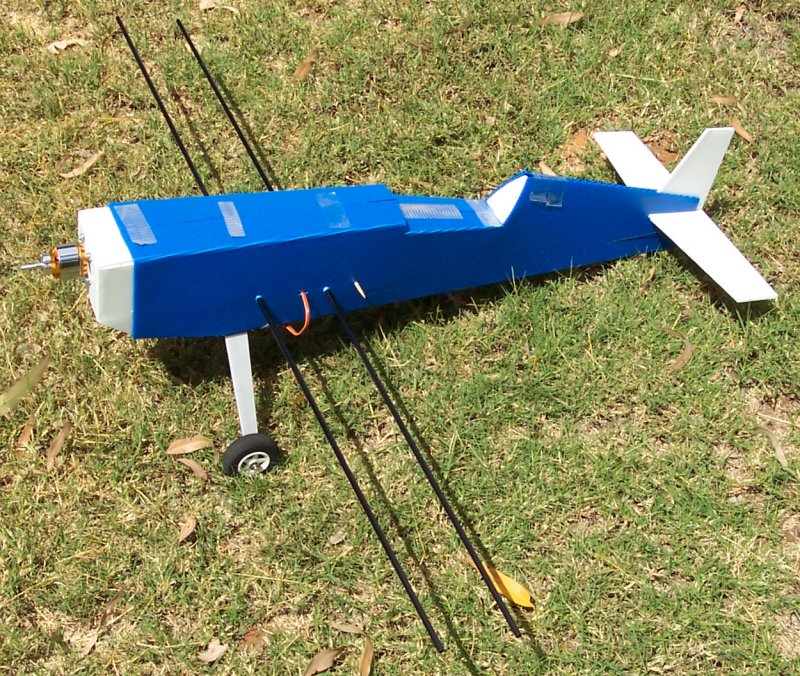

Wingspan: 1200mm, Length: 980mm, Weight: 1080g

Motor: PROPDRIVE v2 3536 1400KV Brushless Outrunner

Motor Controller: HK 50amp Brushless ESC

Battery: Turnigy Nano-tech 2200 mAH 3S 25C (3cell, 50+ amps) Li-poly

Propeller:

APC

11x5.5E

![]()

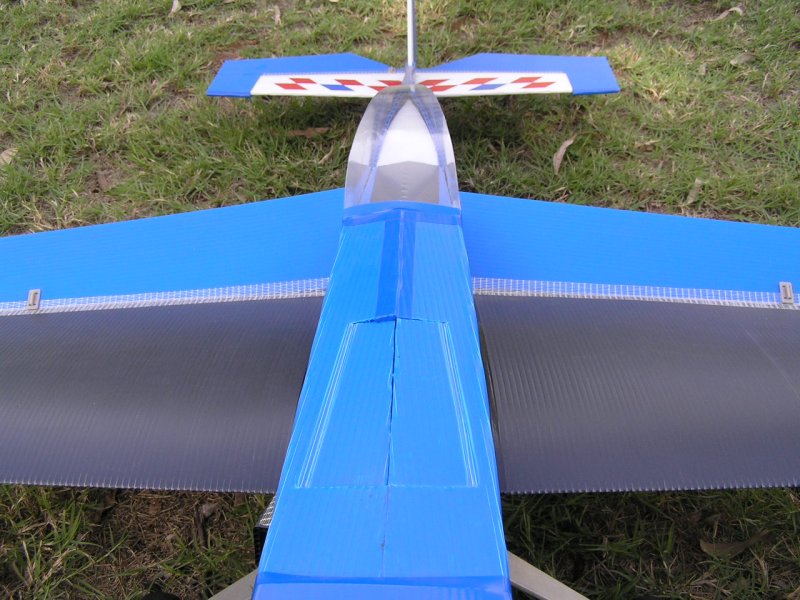

increased aileron size with tapering, overall wing area remains the same.

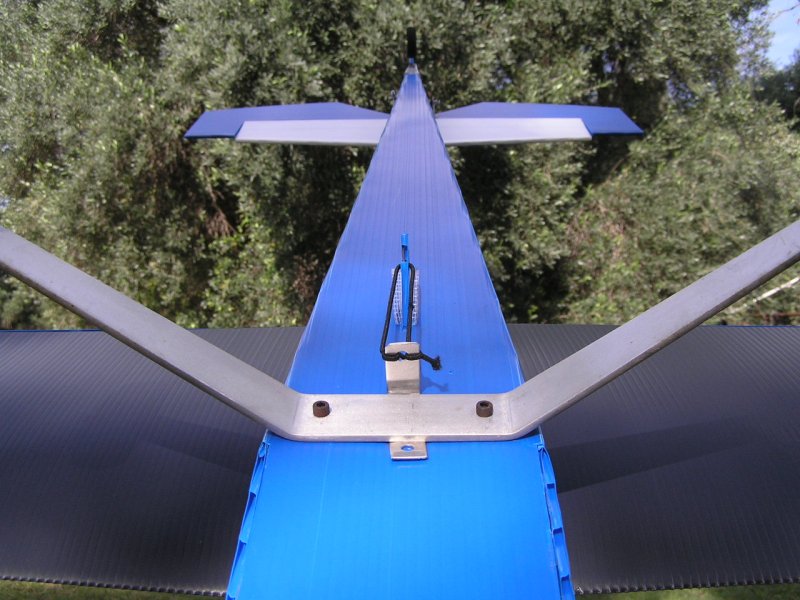

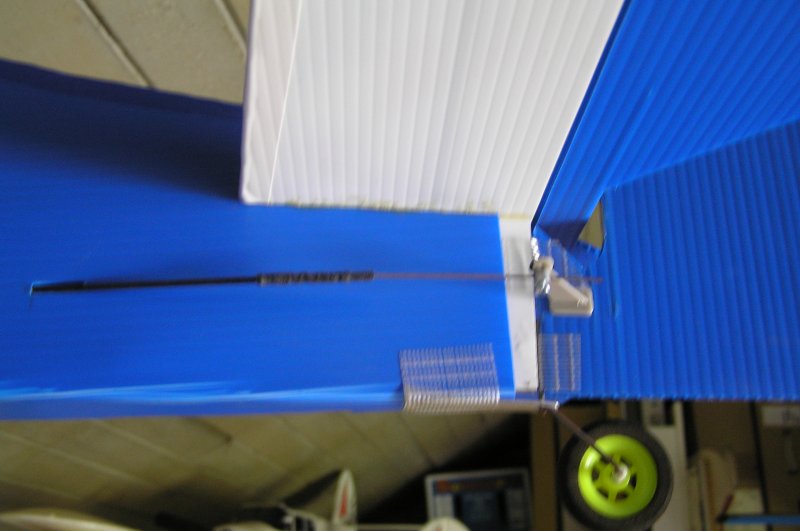

CF control rods to tail surfaces.

Increased control surface travel, up to 45deg.

Higher kV Motor and smaller prop

Mark III Fuse pattern

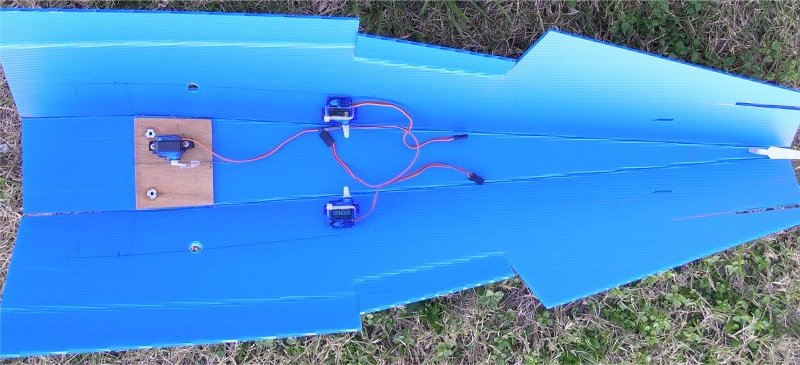

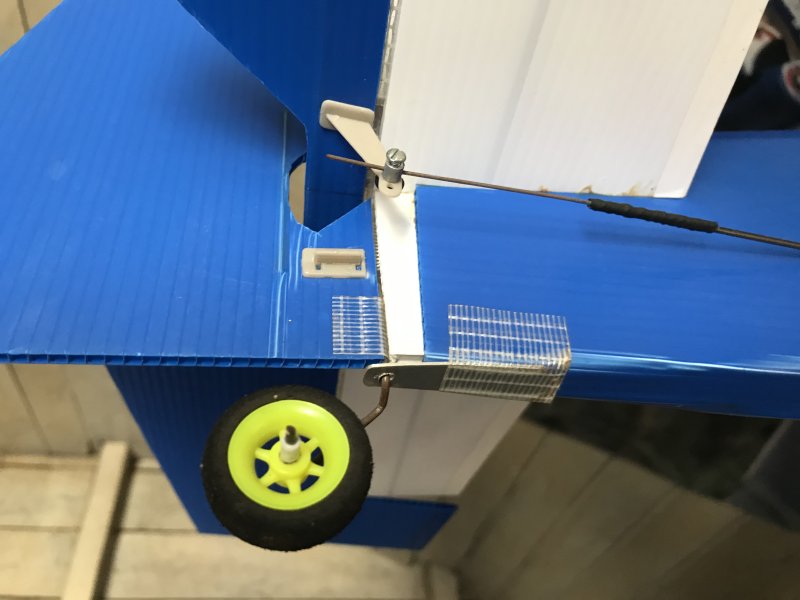

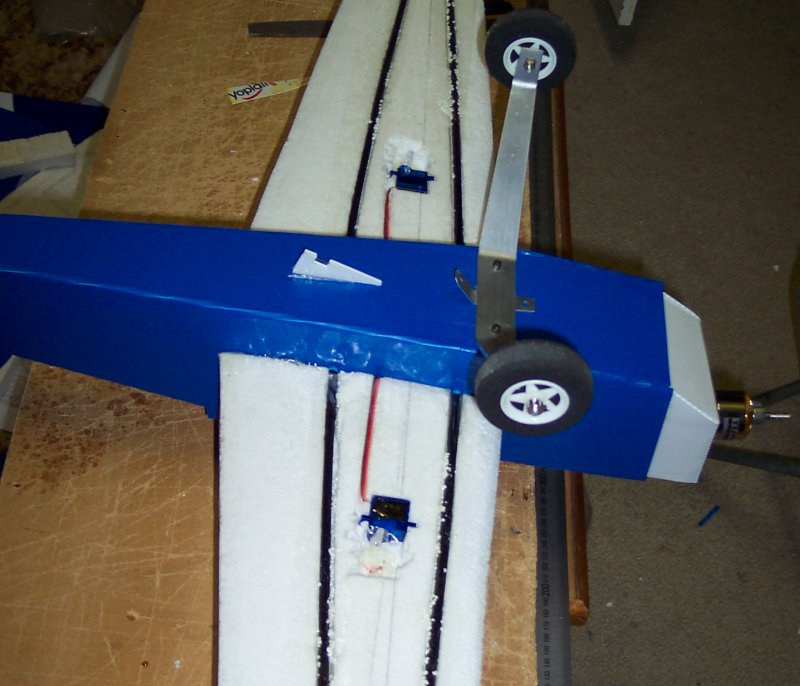

Landing gear mount glued on, Servos mounted, and aluminium tail wheel bracket cut out.

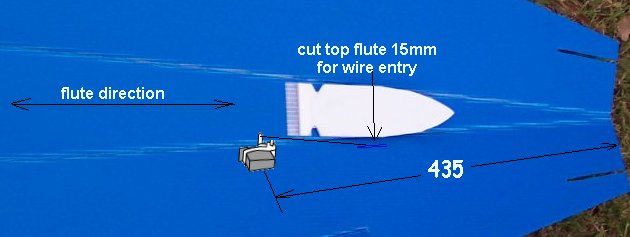

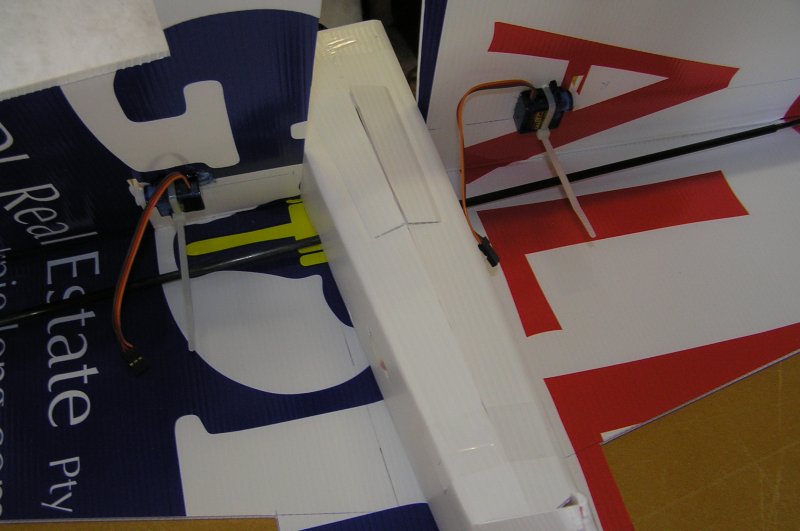

Wing spar holes formed just below wing centre line as the spar is channeled into the underside of the EPS Wing Core.

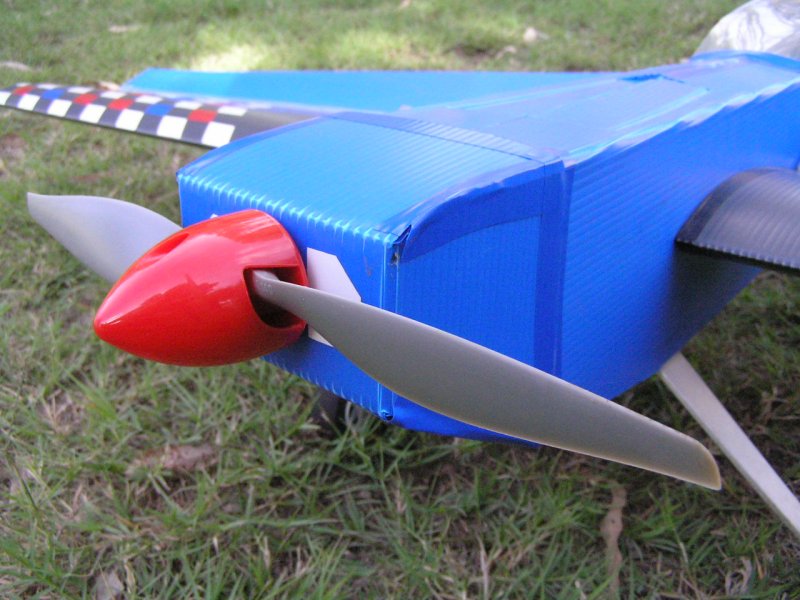

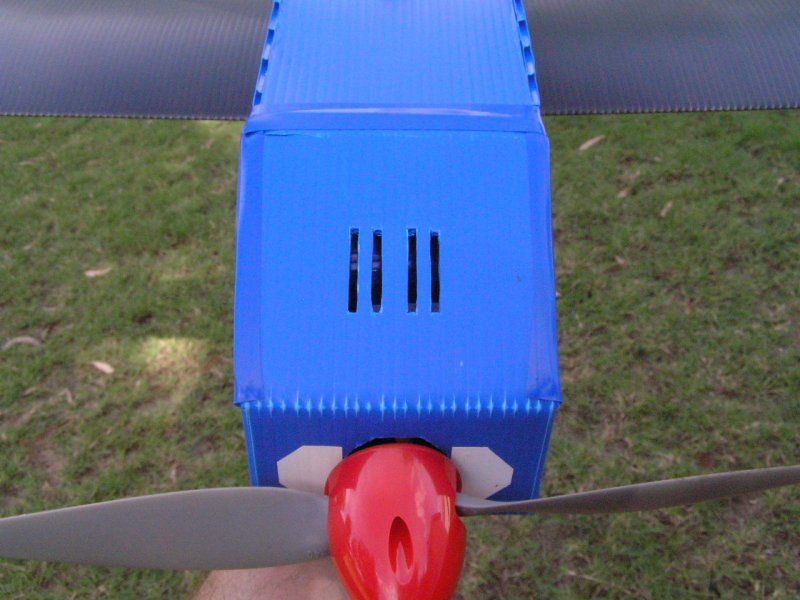

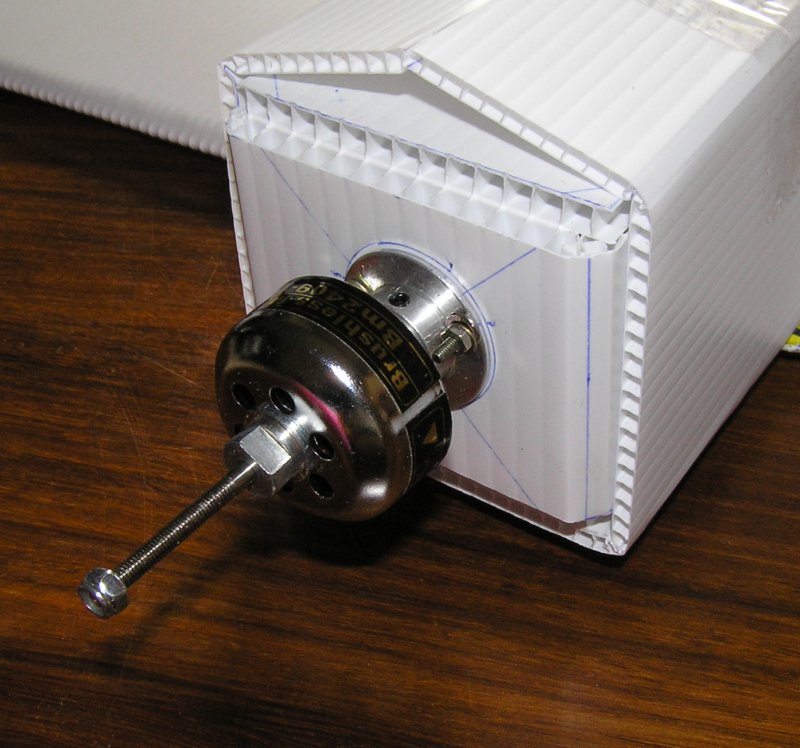

Cowl is formed to suit final firewall and motor layout, finished off with matching electical tape.

air vent for motor on underside of cowl

100 x 275mm Alloy or CF Landing Gear Struts and drop mechanism.

these Control Horns suit the 3mm CorFlute combined with Dubro 845 Mini E/Z Connectors and .032 music wire.

Aluminium support for the tail wheel has a forward tab hooking up into the corflute and then secured with fibre tape.

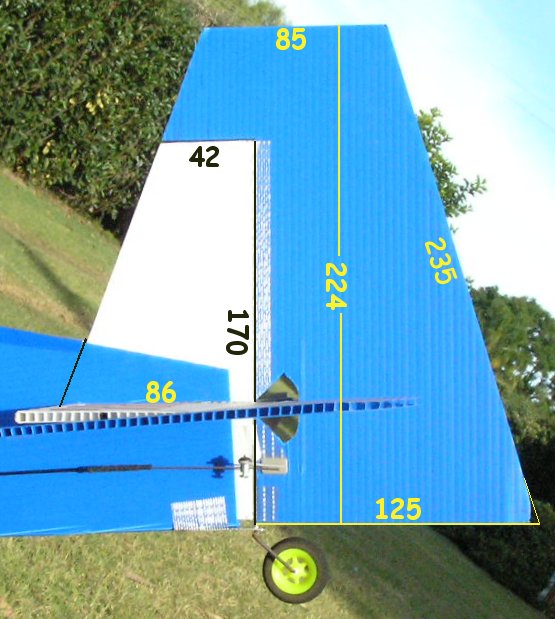

The elevator, horiz. stab. and rudder contain 3mm C/F tube inserts to stiffen and support, especially around the cutout sections. Note the expanded flutes where tube has been inserted.

aileron servo mounted under the corflute, embedded and glued into the EPS wing core

Place a 1" thick foam block behind firewall to protect the battery from nose inpact.

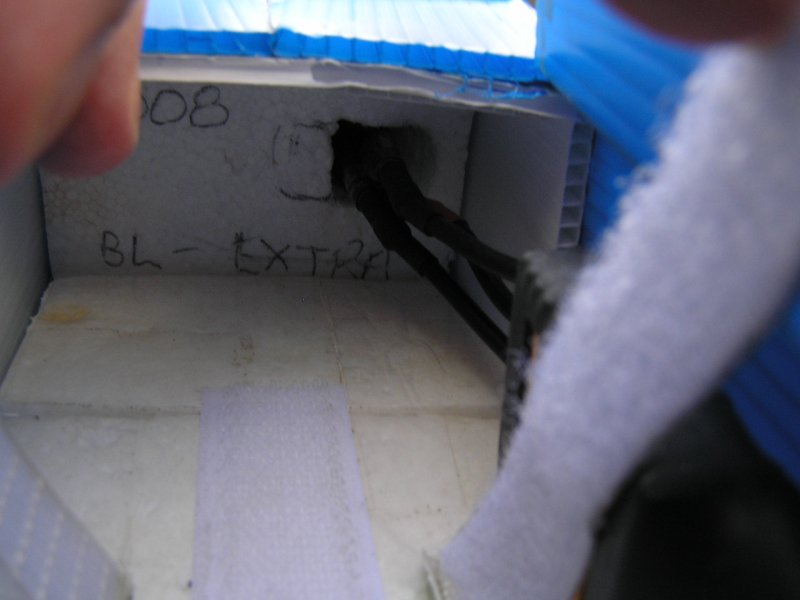

I used a 50amp Opto-isolated ESC, and therefore required a Voltage Regulator to power the RX & Servos.

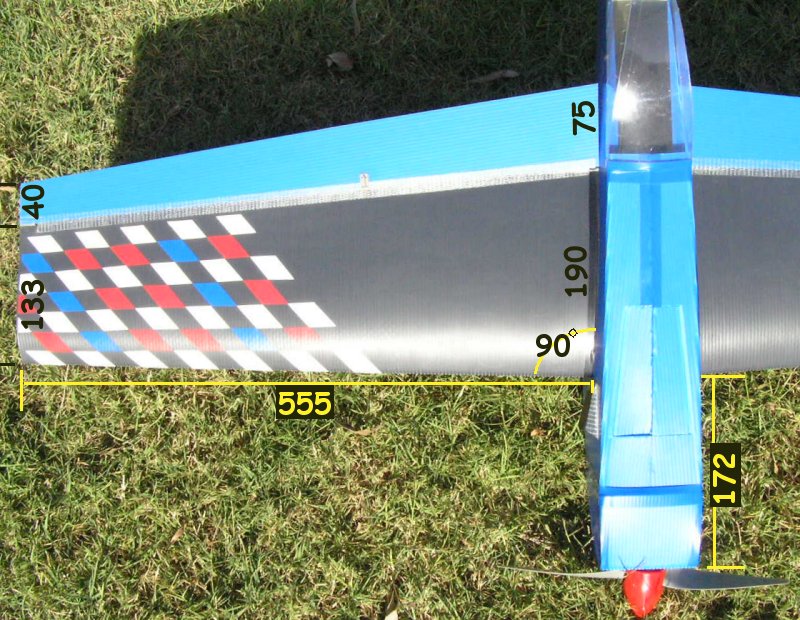

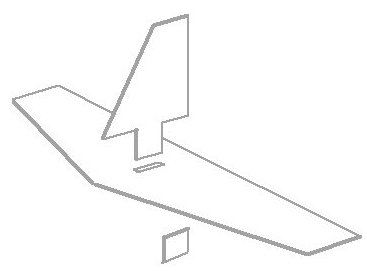

Tail Detail & measurements

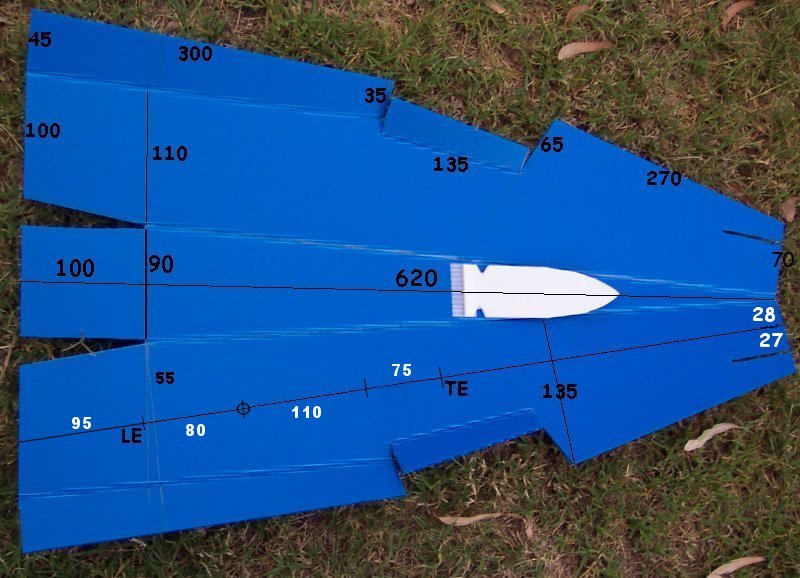

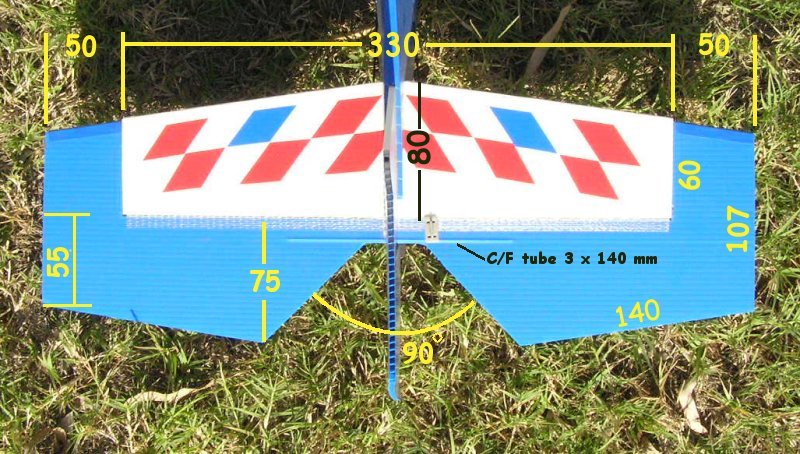

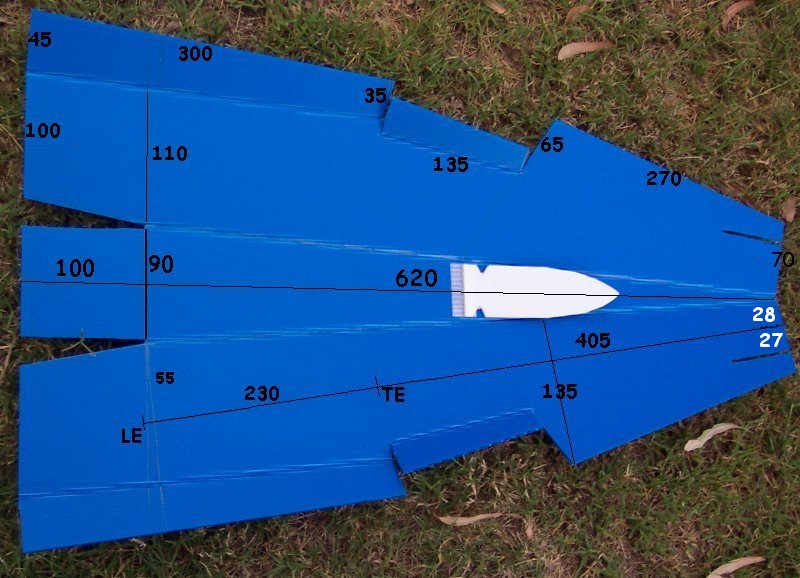

Wing Detail

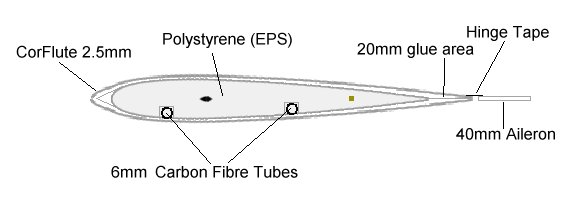

EPS Foam core 525(L) x 157(W fuse)x 100(W tip) x 25mm thick (at cord).

Draw a line down the cord and sand fore and aft of the line to form airfoil shape.

Cut a channel down the underside cord for the wing spar to be expoxied in flush.

Note that folded wing section measurements are top down plan based and do not allow for the shaping.

ie. Allow extra on the trailing edge for folding, then trim to size after glueing with contact adhesive.

Extra - 35 MKII (sold)

--== Specifications ==--

Wingspan: 1180mm

Length: 960mm

Weight: 1080g

Motor: Turnigy TR 35-36C 1100kv Brushless Outrunner

Motor Controller: Turnigy Plush 40amp Brushless ESC

Battery: FlightMax 2200 mAH 3S 30C (3cell, 60+ amps) Li-poly

Propeller:

APC

12x6E

![]()

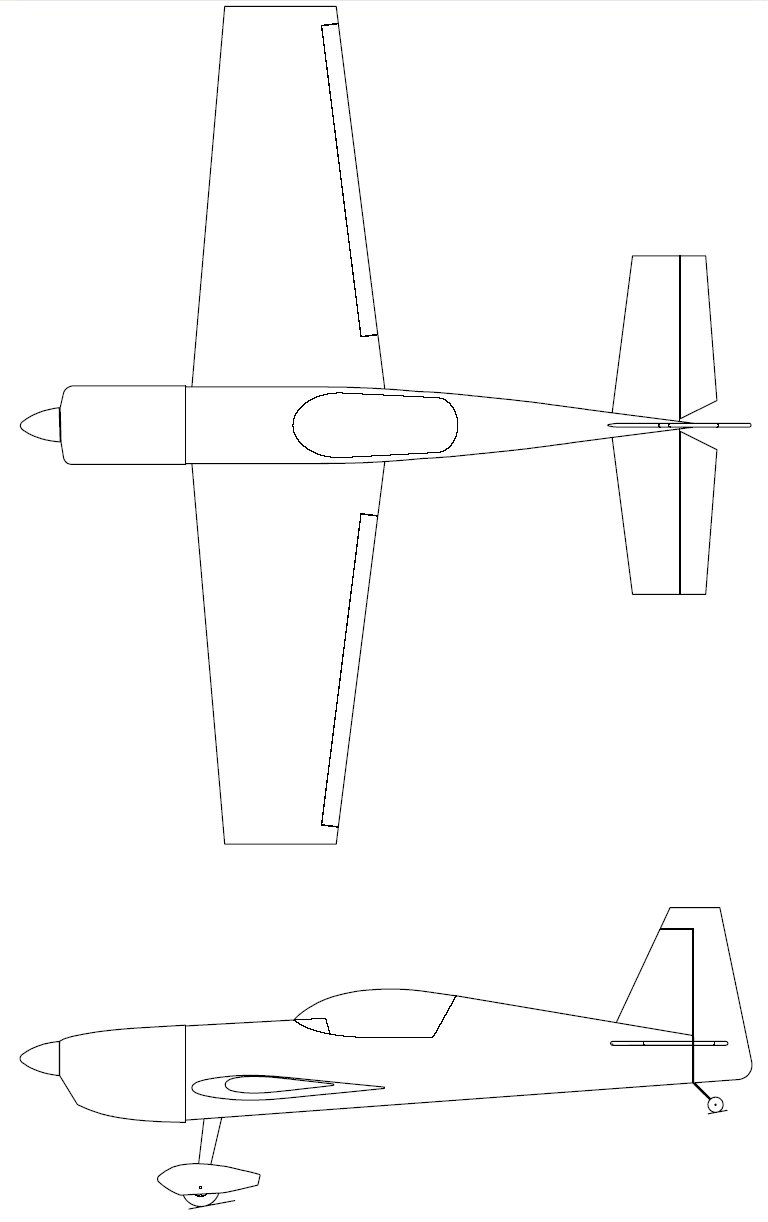

The Base Outline Plan (control surfaces were enlarged significantly)

Cutting out the Fuselage

Cut a small piece of corflute to act as the primary bulkhead at the back of the cockpit, also forming the turtle deck shape.

Glue a plywood piece to the fuse floor as a gear mount. Run 2 BBQ skewers into the flute under the plywood to act as anti-compressors to stop the gear strut squashing the flute when bolted on.

Cut out a Styro foam block as a fuselage inner spacer to run the carbon fibre tubes through. (see note for MKIII about using 8mm square tube) Run a BBQ skewer through the back section to act as an anti-rotation pin for the wing. Slot the vertical stabiliser into the horizontal tail piece.

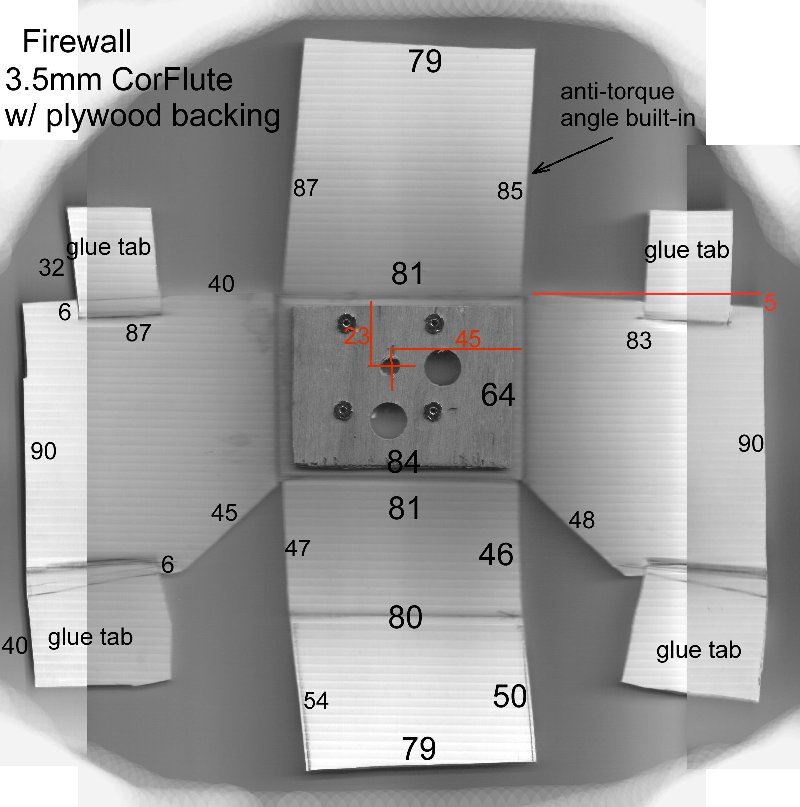

Flat Scan of the Firewall Cutout showing angles

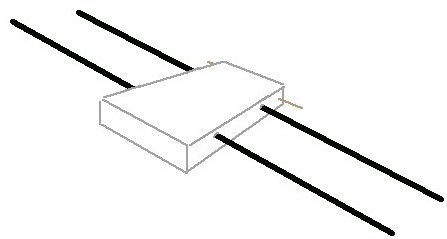

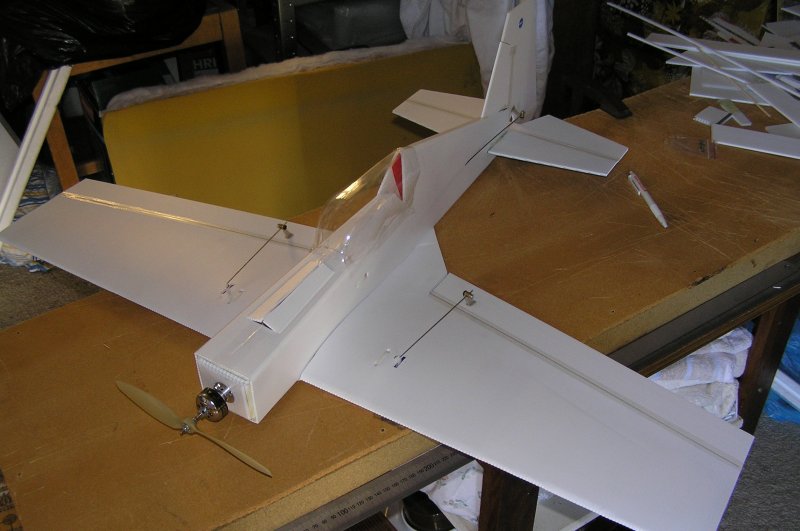

Fuse folded with Motor on Firewall, Gear, Tail & 6mm Carbon Tubes

Alternatively, use 1 x 1000 x 10mm sq C/F Tube for wing spar

Polysterene (EPS) Foam forms the inner wing shape

Wing Foam core 500(L) x 195(W fuse)x 100(W tip) x 25mm (at cord)

EPS glued onto CF Tubes

Flying "Knife Edge"

In Action

Extra - 35 (mk I)

[written off after loss of communication]

BLISter II

Wingspan: 1000mm

Weight: 880g

Motor: KD A22-15M Brushless Outrunner

Prop: 9x6 APC Slowfly

Fuselage, Tail, Tailwheel & Firewall (CorFlute: 3mm yellow, 3.5mm white, 2.5mm black)

Completed

Maiden Flight

Bandits, Six O'Clock!!

No problem, it flies rings around the maggies!

Safe Landing, bandits dispatched.

BLISter I (retired)

[This is the first of my many scratch-builds. It flew OK but was dogged by a heavy tail. The Blister II was much improved with use of lighter CorFlute]

Fitting the Outrunner Motor

Folding the wing from 3.5mm CorFlute Signage, it was a bit heavy.

Almost finished

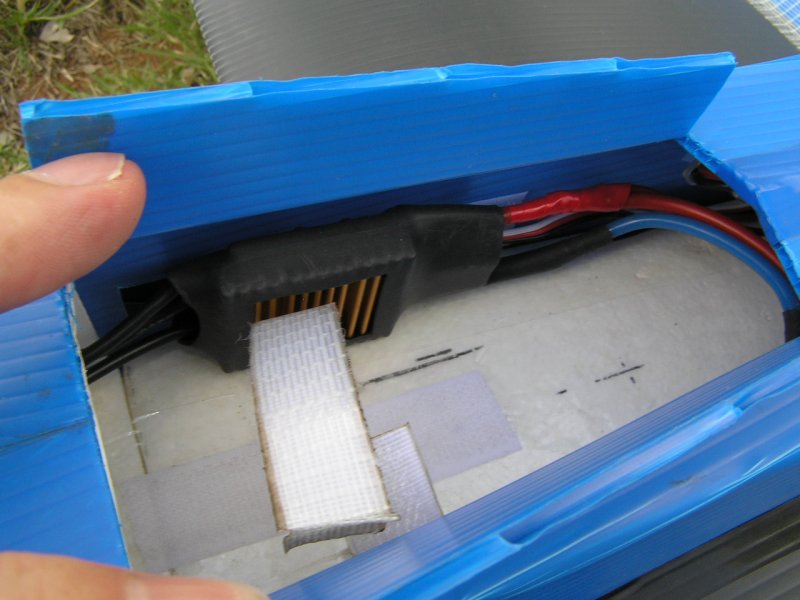

The Battery/Radio gear access hatch

All Done

---======---

page updated 29-Sep-2010

back to BLIS ARC